Loading products

Direct thermal & thermal transfer labels

We stock a wide selection of thermal printing labels for desktop and mobile printers. Our direct thermal, thermal transfer and linerless labels are available in core sizes of 19mm, 25mm, 25.4mm, 76mm and 76.2mm. These are compatible with a broad variety of printers, in particular Zebra, TSC and Kite barcode label printers.

Can’t find what you’re looking for? Get in touch with us at envirolabel@kitepackaging.co.uk.

Need a new printer or looking to upgrade your existing systems? With options for every budget and requirement, we’ve got something for everyone. Explore our range of thermal label printers and printer ribbons now.

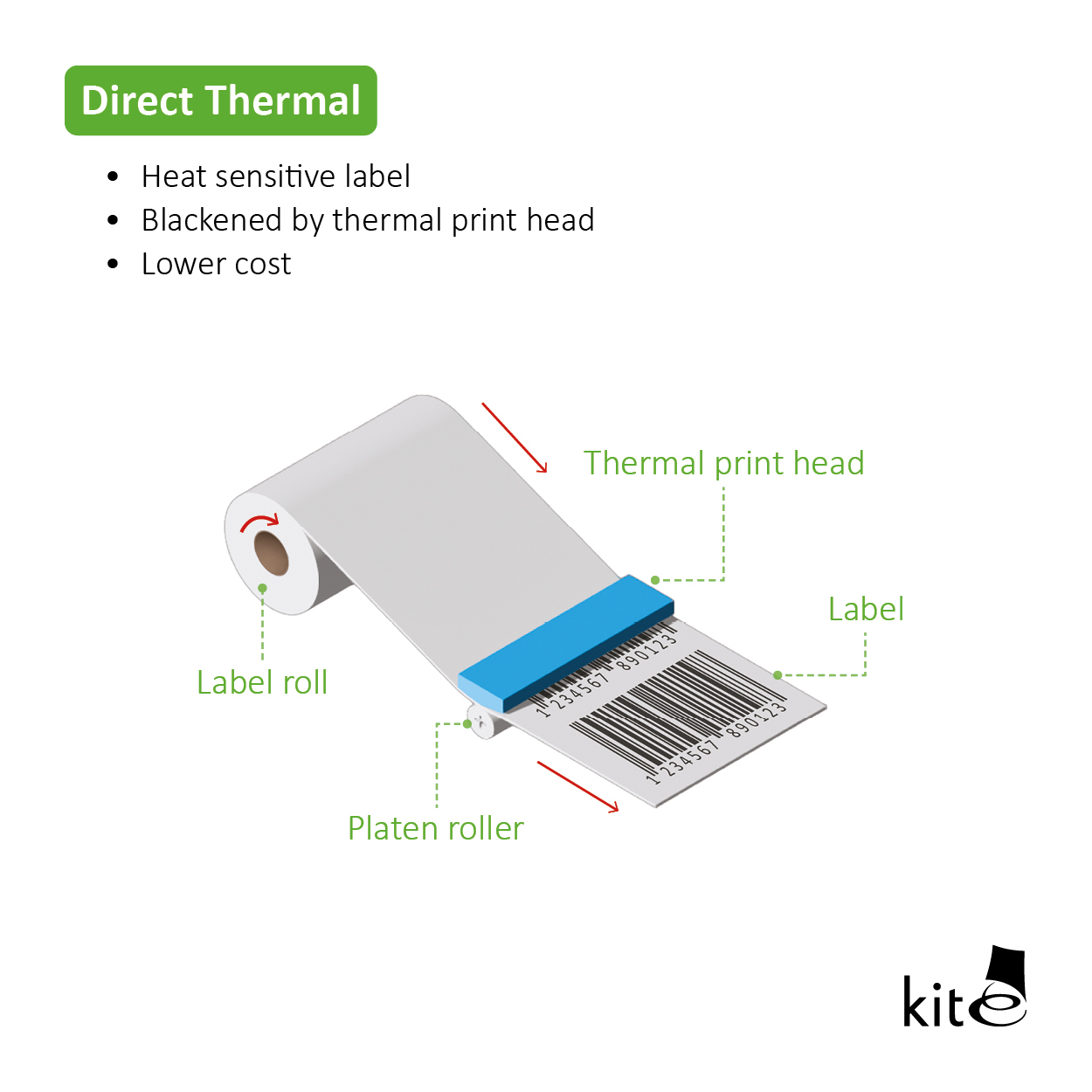

Direct Thermal Paper Labels

Direct thermal labels are coated with a special heat-sensitive layer which darkens when exposed to heat. They are designed for use with direct thermal printers which use heat from a thermal print head to create images or text. Popular for their simplicity and cost-effectiveness, these labels do not require ink, toner, or ribbons for printing, making them a hassle-free solution for many businesses.

We stock our own brand of linerless direct thermal labels. Kite envirolabels solve the issue of managing backing liner waste by removing it altogether. With zero liner waste to worry about, your business can reduce costs, speed up the flow of goods and experience streamlined processes.

What are linerless labels and what are their benefits?

Linerless, or liner-free, labels are a type of self-adhesive label that do not require liner or backing material. Unlike standard labels which have a liner to protect the adhesive layer, linerless varieties have a silicone coating on their surface to prevent the labels from sticking to each other. This allows them to be wound on a roll without the need for backing material, accommodating more labels on a roll when compared to standard labels with liners whilst reducing waste. For this reason, liner-free labels are the ideal labelling solution for businesses seeking to reduce their environmental impact and increase their operational efficiencies.

By eliminating waste and using 40% less paper, these labels offer increased environmental sustainability and can help businesses drive their CSR commitments. However, the benefits of zero liner waste extend beyond just environmental considerations.

Linerless labels also offer:

Thermal Transfer Paper Labels

Thermal transfer labels are coated with heat-sensitive ink or resin that is transferred onto the label face using heat and pressure. These labels are designed for use for with thermal transfer printers, which use a thermal print head to melt the ink or resin onto the label’s surface. This printing method provides durable and long-lasting prints, making them suitable for applications where resistance to moisture, chemicals and abrasion is required.

Thermal Transfer Ribbons

Thermal transfer ribbons are a consumable component used in thermal transfer printing. Made of a thin layer of ink which is coated onto a polyester film, the ribbon is passed through a thermal transfer printer along with the label. When heat is applied to the ribbon, the ink transfers onto the label, creating desired image or text.

Thermal transfer ribbons come in wax, wax-resin and resin. We stock wax ribbons from the biggest names in the industry, Zebra and TSC. These are suitable for printing on paper labels, provide good print quality for barcode labelling purposes, and offer the best possible value. Compatible with most coated and non-coated paper labels.

When selecting a thermal transfer ribbon for your printer, it is worth considering the following factors:

Durability and Resilience:

While we only stock wax and wax-resin ribbons, please do get in touch with us if you would like to explore options in resin as we are always open to expanding our options based on your needs.

Remember, the right choice depends on your specific application and label life requirements. Call us for advice if you’re not sure.

Ribbon Type / Wind Direction:

Ribbon Size: