Loading products

U-tulip foam edge protection

Manufactured using low-density polyethylene that has unique properties to ensure it is extremely flexible, whilst still maintaining a tight grip on edges. One of the most popular types of edge protection, particularly in the furniture and framing industry, it is economical, easy and quick to handle, and flexible.

These U-tulip shaped foam profiles have been developed to efficiently protect the most sensitive parts of the product - the edges. Thanks to the hugging design of its lips, the U-tulip grips the edges automatically, and protects against knocks, scrapes and scratches.

*Please note that our U-tulip foam protection is not fire-rated.

There are eight different sizes to choose from in Kite’s range, to accommodate really narrow and much wider edges. Supplied in lengths of two metres as standard; however, it can easily be cut to specific requirements.

This foam offers a range of additional benefits which are essential when packaging large fragile items such as furniture, glass, picture frames and metal sheeting. It is shock-absorbent, water-resistant, doesn’t scratch or damage smooth surfaces, and is temperature resistant (from -40C to +100C) - so is the perfect product for packaging goods for transit – particularly in various climates and atmospheres.

100% recyclable and chemically neutral, making it a more environmentally friendly way to package high-value products.

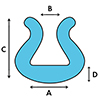

Dimensions

The range is defined by its useable dimensions (for example 5-15mm) which is measured according to its ‘A’ (widest) and ‘B’ (narrowest) opening. For example, when an edge is 16mm thick a 15-25 foam is needed, however, if an edge is 14mm thick a 5-15 foam is required.

The C dimension is the length of the profile sides. Dimension D is the thickness of the profile bottom.

Windscreen foam edge protection

Our windscreen foam edge protection offers an innovative and practical solution for safeguarding windscreens, window panes, shower screens or any other fragile panes of glass/plastic that do not have a rubber lip, along with sheets of glass and metal, mirrors and heavy goods with sharp edges. The foam acts as a cushioning barrier, offering impact absorption protection to minimise the risk of fragile and delicate items chipping, cracking or scratching during handling, storage and transit.

These foam edges are made from PE-LD foam and are CFC- and HCFC-free, ensuring compliance with regulations in countries where the use of ozone-depleting substances like CFCs and HCFCs is being phased out or not permitted at all. PE-LD foam refers to foam packaging that is made from low-density polyethylene (LDPE) and is commonly used in packaging due to its lightweight, flexible and durable nature. As such, these foam edge protectors provide excellent cushioning and shock absorption, making them ideal for protecting fragile or delicate items. As LDPE foam is lightweight, it keeps shipping costs to a minimum and contributes to lower fuel consumption and carbon emissions during transportation. Along with this, our foam edge protection for glass and windscreens is recyclable and will support your sustainability efforts. LDPE foam is also resistant to moisture, chemicals and most solvents, offering protection against environmental factors and contaminants.

Our foam edge guards are supplied as a continuous coil and can easily be cut down to the required size, granting flexibility of use. Its additional inner hole reinforcement prevents any sharp edges from piercing the profile, enhancing overall protection.

Looking for corner protection? Check out our foam corner protectors.

Click here for our recycling guide

See our range of u-tulip edge protection and how they can be used