Kite blog

Three Questions to Ask Yourself When Buying a Box

With so many choices available, selecting the ideal cardboard box for your product can feel overwhelming. At Kite Packaging, we offer more 200 different cardboard boxes, so where should you begin?

To help, we've compiled our top three tips for picking the perfect cardboard box for your needs.

Join Dennis, a Kite Packaging technologist, in our Mobile Packaging Laboratory as he walks you through the three key questions you should ask yourself when buying a box. This will help you choose the right solution to protect your product, showcase it, and stick to your budget.

Let’s jump right in and explore the three questions that will guide you to the perfect box for your needs.

Question 1: What Size Box Do I Need?

Choosing the right box size is crucial to ensuring your product arrives safely, looks great and keeps costly damages to a minimum.

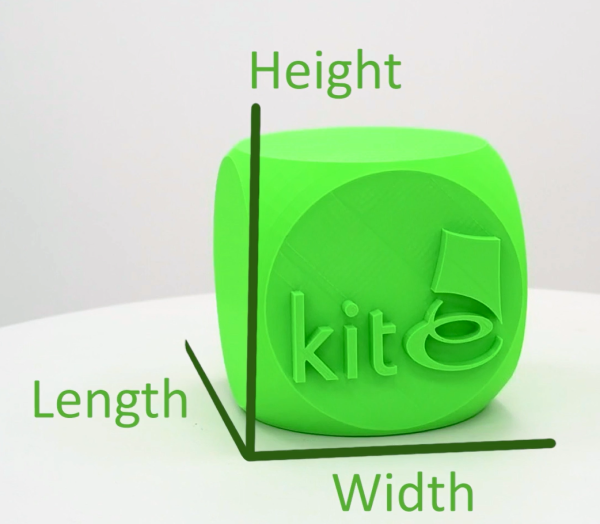

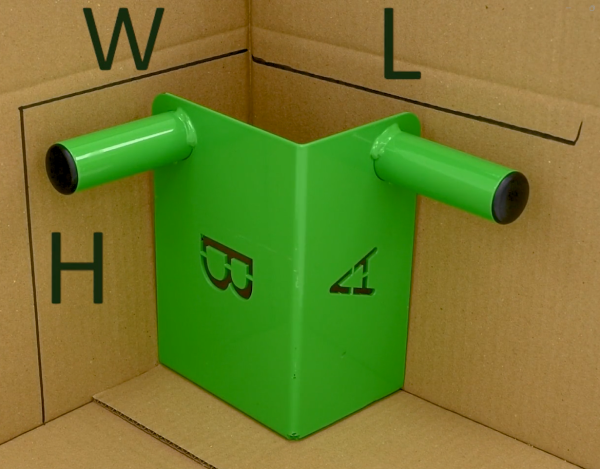

To figure this out, start by measuring the three dimensions of your product. First measure the length and the width, which will form the footprint of your box.

Then, measure from the top to the bottom, which gives you the height of your box.

For irregularly shaped items, imagine drawing straight lines around the outermost edges of your product to create a rough outline, then measure these dimensions for a box that fits.

Don’t forget to account for any parts that stick out from your product or any accessories you plan to include. And if you’re using protective packaging, like void fill, make sure you allow room for that too.

Question 2: What Strength of Board Do I Need?

To make this easier, we can break it down into a few key questions:

- How heavy is your product?

- Where is it going?

- How vulnerable is it?

We offer a variety of board strengths in our range, which we refer to as grades. These grades are determined by the paper weights and the number of flutes* in the board. Picking the right grade for your product will help protect it, present it well, and even save on any redistribution costs.

Board Grades

- Single Wall Boxes: These are made from three layers of paper – two liners with a single flute in between. Ideal for light to medium-weight products, whether they’re shipped on their own or palletised.

- Double Wall Boxes: Made up of five layers of paper – two fluted mediums separated by three liners. The extra fluting boosts strength and improves compression performance, making these boxes better suited for heavier products that might strain on single wall carton.

- Premium Single Wall Range: this is a performance alternative to double wall, offering greater environmental benefits. With a thicker fluting and heavier gsm* paper, it provides better burst and compression strength while reducing material content, weight, and palletisation costs. This range is a top choice for those seeking a balance of strength and sustainability, reducing material usage while offering superior protection.

- Extra Heavy-Duty Range: Designed for heavy goods, these boxes offer increased calliper* of board and weight of papers for maximum strength and compression. They are mostly used for export.

Kite details both internal and external dimensions on our website to aid dispatch.

Question 3: What Style of Box Do I Need?

Whether your priority is shipment presentation or packing efficiencies, we have a style to match these needs and more.

- Shipping cartons (0201s*): The most common box type, with flaps at the top and bottom that can be sealed with hand tape or processed through machinery.

- Die-cut boxes*: Designed to enhance presentation, these boxes are suitable for thinner items and can fit through letter boxes. Die-cut boxes are a versatile solution that can be tailored to fit your product’s exact shape and branding needs, offering a higher-end appearance for retail or presentation purposes.

- E-Commerce boxes: Pre-glued boxes with a peel-and-seal top, so there’s no need for external tape. They also include a tear tape for easy opening, creating a seamless and enjoyable unboxing experience for customers.

Conclusion

Those are the three questions you need to ask yourself when buying a box.

If you’re not using one of our e-commerce boxes, don’t forget to stock up on tape. And if there are any gaps in your box, you will also need to some void fill.

Explore our full range of packaging solutions and discover how Kite Packaging can meet your needs.

Packaging terms

Flute – this refers to the wavy, or corrugated material inside the box that provides strength and cushioning.

Calliper – in packaging, calliper is the combined thickness of various layers that make up a material, such as the linerboards (the smooth outer layers) and fluting (the wavy inner layer) in corrugated board. It is measured in millimetres.

Think of calliper as the thickness of the board. The thicker the board, the more durable and protective it will be for your product. For example, a single-wall box with a calliper of 3mm will be less durable than a double-wall box with a 6mm calliper.

Board grade – refers to the specific type and strength of corrugated board used to make boxes. It determines the box’s durability, ability to protect its contents, and suitability for various applications

Gsm – grammage (gram per square metre) of the paper used in the production of packaging materials like corrugated board. It determines the strength, stiffness and durability of the material.

A higher grammage means the paper is heavier, thicker and stronger, offering better protection for the contents inside the packaging. On the other hand, lower grammage may be lightweight and cost-effective but could offer less protection.

- Linerboard typically has a higher grammage as it provides structural strength.

- Fluting may have a lower grammage since it provides cushioning and rigidity.

0201 – a term from the FEFCO (European Federation of Corrugated Board Manufacturers) box design code. It is an internationally recognised standard for box styles.

Die-cut boxes – Die-cut boxes are custom-designed packaging made to fit specific product shapes, often used to enhance presentation or branding.