Kite blog

Kite Packaging Shortlisted at UK Packaging Awards 2022

We are delighted to announce we have been shortlisted for the following categories at the UK Packaging Awards 2022:

- Corporate Social responsibility Initiative of the Year

- Design Team of the Year

- Supply Chain Solution of the Year

- Packaging Company of the Year

A massive thank you to our incredible packaging specialists and the wider Kite team for all the hard work and effort they have put into making us leaders in packaging.

Packaging Company of the Year

Since our founding, Kite’s unique philosophy of employee-share ownership has been crucial in making us the fastest-growing, most profitable packaging distributor in the UK.

In 2021, online shopping and the need for packaging sky-rocketed, making it a record-breaking year for Kite. With an OTIF of over 99% and increased stock value at £11.919m, successful business growth led to acquisition of ShredHouse and our new Distribution and Central Services Centre, increasing our footprint by 200,000 sq. ft.

We launched Kite’s Sales Academy, taking on ten Business Development trainees, welcomed new graduates, and saw five team members enrol onto the Higher Degree Apprenticeship Packaging Professional (HDAPP) at Sheffield University.

As R&D is pivotal, we designed and built our own Mobile Packaging Laboratory (MPL). This £600,000 investment houses our latest environmentally-focused systems, products, drop test facility, presentation screens, 3D scanner, and more. Supported by our specialists teams, it visits customers to showcase bespoke design solutions.

Also registering as carbon neutral under scopes 1 and 2 with future focus to achieve scope 3, we reduced customers plastic and CO₂ use by 398 and 920 tonnes respectively.

Design Team of the Year

Constantly faced with sustainability challenges, Kite’s specialist teams aim to reduce, reuse, recycle and replace harmful packaging components with favourable, eco-friendly ones.

Our AMED teams and packaging technologists minimise usage of materials, focusing on durability to facilitate reuse, reducing environmental impact during production and avoiding issues of sustainable disposal.

The ‘in-the-box’ team looks at replacing traditional plastic products with intelligently designed paper packaging. One such example is hive paper, a roll of which packages the same volume of products as four rolls of bubble wrap, increasing sustainability and cost-effectivity.

Finally, our S2 division focuses on load retention and reduction in usage where plastic is necessary through technologic improvements and increased awareness. Their on-site audits have reduced businesses’ plastic usage by 290 tonnes since 2019 without sacrificing safety or functionality.

Packaging designed for a circular economy

This is best demonstrated through the example of a customer wanting to enhance their custom packaging environmentally. Originally, a corrugated outer holding and unsustainable stratocell foam fittings secured the part. The redesign consists of fully kerbside recyclable corrugated fibre board, feeding into a circular economy which recycles and remakes packaging repeatedly.

Now with a reduced carbon footprint and increased sustainability, the new containers hold two parts per box, halving the quantity of outer boxes needed and materials used, decreasing carbon emissions via transportation.

Consumer engagement

Kite support consumer engagement throughout the process of custom designed packaging, travelling directly to customer sites for maximum engagement and understanding of their supply chain. The recent £600,000 investment into our MPL invites customers aboard to discuss their requirements, test solutions and view sustainable alternatives with our experts.

Our in-house designed and built ‘test-cube’ shows customers the performance of their packaging after multiple drop tests. Load retention audits identify opportunities for plastic reduction, saving money and the planet, and our latest 3-D scanning technology takes products into the 3-D world for micro-detail design work.

Supply Chain Solution of the Year

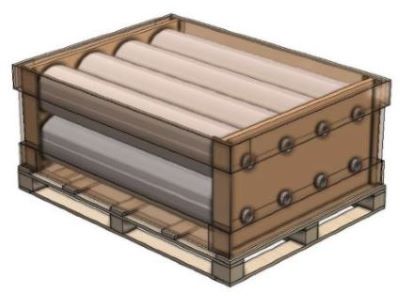

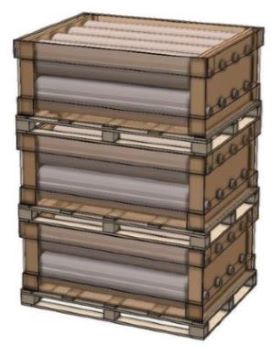

A client approached us to improve an existing transit pack lacking in stability and collapsing under weight of products, causing damage and unhappy customers. Its assembly process, storage requirements and eco credentials were also evaluated.

The outcome, after real time international transit testing and lab-based compression testing, is a fully recyclable pack with a cap, tray and sleeve redesign improving stability and stacking strength. Materials used were reduced by 41% and packing time by 50%, resulting in minimal wastage during the UK manufacturing process. All components now come flat-packed for easier assembly and storage efficiency.

Corporate Social Responsibility of the Year

Crown Paints needed a sustainable solution to secure round buckets of paint onto square pallets, with the ability to withstand excessive g-force. This came following issues with pallets falling over in transit, resulting in yearly losses of £400,000-500,000 in product, clean-up operations, and supply chain issues.

We tested the pallets at the Duoplast tech lab in Germany to determine their current stability. Our packaging specialists then joined forces with Robopac, creating an automatic pallet wrapping machine. This precisely applies the exact amount of film required eighty-five times an hour. We developed a virgin film reducing plastic consumption and another film containing 30% recycled content, reducing plastic consumption and CO₂ emissions by 50%.

Crown Paints now have an automatic pallet wrap machine, which takes pallets from the production line into the wrapper, securing them with a waterproof seal and saving £400,000-500,000, 40 tonnes of plastic, and 92 tonnes of CO₂ a year.

The UK Packaging Awards will be taking place on Wednesday 19th October 2022. Watch this space for news on how we do!

Need bespoke packaging solutions like the ones we mention above? Call us on 02476 420065 to see how we can help you.